Unlocking the secrets of the Achilles’ heel

Microstructure and micromechanics of the interface between bone and tendon

2017-02-28 – News from the Physics Department

Some 8000 torn Achilles’ tendons are treated in Germany every year. And that even though it is the strongest tendon in the human body. It connects the ankle bone to the calf muscle and holds up to ten times the body’s weight. The tendon got its name from the – nearly – invulnerable Greek hero Achilleus, who was doomed by an arrow that struck him in his heel.

“Although orthopedic doctors treat patients with tendon injuries every day, we still know very little about the precise histological structure at the direct interface between bone and tendon: The biochemical processes, the micromechanics and the microstructure of the tissue have hardly been researched,” reports PD Dr. Rainer Burgkart, senior physician and research director at the Chair of Orthopedics and Sports Orthopedics at the TUM.

Thin fibers, perfect hold

Together with an interdisciplinary team of biochemists and biophysicists at the TU Munich, within the framework of the newly founded Center for Functional Protein Assemblies (CPA) and the Munich School of Bioengineering (MSB), the physician has now deciphered the secret of the Achilles’ heel: The experts discovered a tissue layer between the tendons and bones that comprises extremely thin protein fibers and ensures the remarkable strength.

That is why athletes can take hurdles during a sprint, jump over high bars and survive hard landings, all without damaging the bond between the tendon and ankle bone. In fact, the tendon is more likely to tear than to separate from the bone tissue.

“Hitherto, it was thought that the tendons attach directly to the bone. In fact, though, there is a transitional zone. Here the tendon tissue splits into dozens of fine fibers with a characteristic biochemical composition,” explains Prof. Andreas Bausch, Chair of Cellular Biophysics and director of the interdisciplinary research group. “The thin fibers are firmly anchored to the jagged surface of the bone and mechanically extremely durable.”

Together from the start: medicine, physics, Chemistry and engineering

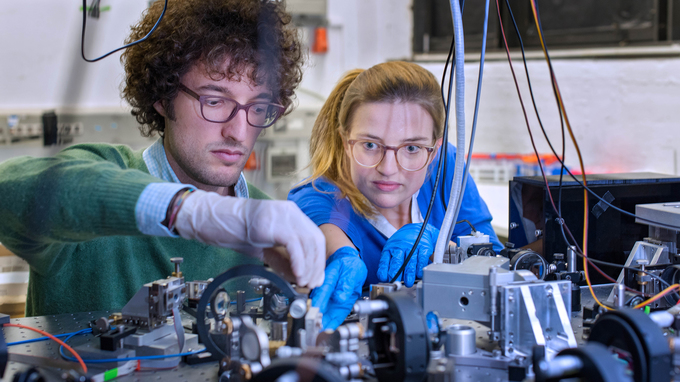

The fine fibers were discovered using a new interdisciplinary research approach: “The actual innovation in the work lay in the fact that we brought together various medical, physical and engineering processes,” says Bausch.

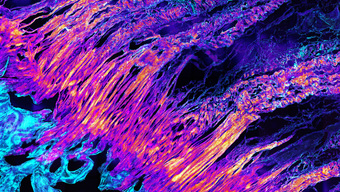

A piece of porcine bone with tendon, meticulously prepared by the physicians, was clamped and fixed in an apparatus at the Chair of Cellular Biophysics. Next, the researchers aimed a microscope at the boundary layer, along which the tendon and bone grow together. Using multiscale microscope technology, dozens of images were taken and compiled into a single, large image. “In this way, we could make visible the structure of the fine, split fibers,” reports Bausch.

Then the team used fluorescing antibodies to get specific proteins to light up. This is where it became clear that the thin fibers have a biochemical composition different from that of the actual tendon. In the third part of their experiment, the researchers moved the tendon back and forth under load and filmed the fibers. The result: Depending on the loading direction, different fibers are active and stabilize the contact.

The light microscopy investigations were augmented using high-resolution images of an electron microscope. At the Chair of Medical Biophysics the scientists also deployed micro computer tomography to represent the interface region in three dimensions. In addition researchers at the Chair of Organic Chemistry analyzed the various proteins in the tendons and interface fibers.

Approaches for medicine of the future

“These results allow us, for the first time, to understand the biochemical processes in the contact zone between bones and tendons, which give our locomotor system its extreme strength,” summarizes Bausch.

Possible applications will arise in material research, as well as in medicine: Engineers will be able to produce innovative connections between hard and soft materials. And orthopaedic doctors will use the results in tumour surgery to attach tendons to implants.

The research arose out of a project at the International Graduate School of Science and Engineering (IGSSE) and was supported by the Excellence Cluster Nanosystems Initiative Munich (NIM), both funded by the German Research Foundation (DFG) within the framework of the Excellence Initiative.

- Desk

- Dr. Andreas Battenberg, Dr. Johannes Wiedersich

Publication

Links

Contact

- Prof. Dr. Andreas Bausch

- Technische Universität MünchenJames-Franck-Str. 1, 85747 Garching, GermanyTel.: +49 89 289 12480E-mail: abausch@mytum.de