Perfectly suited: New ways in battery research

2019-10-17 – News from the Physics Department

New method for investigating lithium-ion batteries

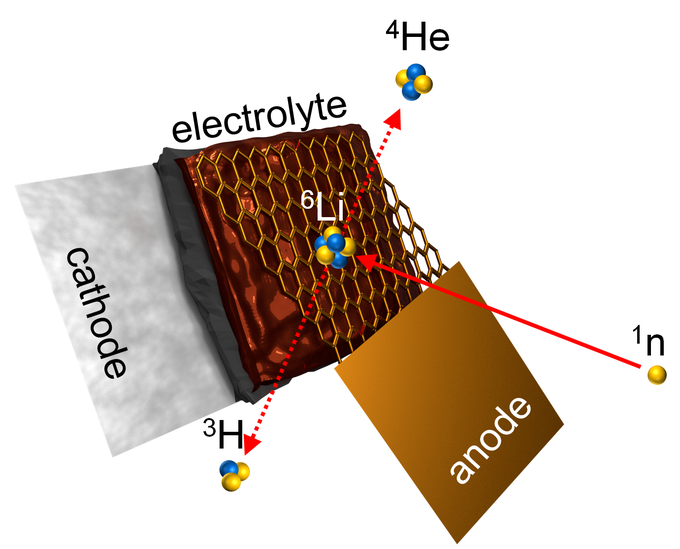

The new instrument named “N4DP” is set up at the PGAA facility and makes use of the extremely high neutron capture cross sections of specific nuclei. Low-energy neutrons are captured by those nuclei in the sample which subsequently decay into two charged particles. The particle type and their respective energies are kinematically well defined and depend on the capturing nucleus. Since charged particles lose energy when traveling through matter, one can determine the depth of their origin by measuring their residual energy when leaving the sample. This allows for the precise determination of their density distribution in the sample. In contrast to other multi-element techniques of activation analysis (PGAA, NAA), neutron depth profiling is suitable for a couple of isotopes. Lithium-6 is one of the most prominent ones, which is the reason why NDP is particularly well suited for lithium-ion-battery research. The figure below shows the principle of NDP in the case of lithium-6. Using this method ex situ measurements are possible, where electrodes are removed from batteries after charging to different states-of-charge or after different numbers of charge-discharge cycles and are then exposed to the high neutron flux at the N4DP focal point. Additionally, the method also allows for operando measurements where the whole battery can be analyzed during the battery charging and discharging process.

Lithium-ion batteries using silicon-graphite electrodes

They characterized a promising new electrode candidate for silicon-graphite electrodes which has a silicon fraction of 35%. However, this silicon-based anode electrode also suffers from a loss in capacity with the number of charge-discharge cycles. The scientists in this cooperation identified two reasons for this: firstly, upon extended charge-discharge cycling the anode electrode substantially expands in its thickness and increases in mass. The material for this mass gain is provided by the electrolyte which undergoes side reactions at the anode electrode with the electrolyte, forming a so-called SEI layer (“solid electrolyte interphase”). Secondly, morphological changes of the silicon nanoparticles largely increase their surface area, which further increases the SEI formation. Both results were confirmed by the research group using conventional electrochemical and imaging techniques. Using NDP, they could go one step further for the first time and take a detailed look at the electrode mass increase. They realized that the increasing amount of lithium immobilized in the SEI with increasing numbers of charge-discharge cycles proceeds uniformly across the thickness of the silicon-graphite electrode. This is an important finding, because the scientists can now exclude ionic and/or electrical transport limitations across the electrode thickness as the possible cause for the observed capacity loss upon extended cycling. Thus, the observed degradation is not due to clogging of the electrode pores by SEI products, but is predominantly caused by the volume expansion/contraction of silicon nanoparticles over a charge-discharge cycles as well as by the gradual surface area increase caused by the morphological changes of the silicon nanoparticles.

Depth-resolved measurements during charging and discharging

Furthermore, it is possible to go beyond the previous ex situ measurements of the SEI. “The possibility of a depth-resolved operando measurement enables us to go further than just a characterization of the passive SEI layer. We can also look into the reversible lithiation, which happens during the charging and discharging process.”, says Markus Trunk, part of the TUM collaboration, while preparing with his colleagues Morten Wetjen and Lukas Werner the samples for the next N4DP measurements.

Publications

Just lately the TUM cooperation – consisting of the MLZ, the professorship of particle physics at low energies, the chair of technical electrochemistry, and the central technology laboratory of the physics department – contributed significantly to the understanding of a new kind of lithium-ion batteries using the N4DP instrument. They published their recent results in three different papers:

- Materials science applications of Neutron Depth Profiling at the PGAA facility of Heinz Maier-Leibnitz ZentrumM. Trunk, M. Wetjen, L. Werner, R. Gernhäuser, B. Märkisch, Zs. Révay, H.A. Gasteiger, R. Gilles

- Quantifying the Distribution of Electrolyte Decomposition Products in Silicon-Graphite Electrodes by Neutron Depth ProfilingM. Wetjen, M. Trunk, L. Werner, R. Gernhäuser, B. Märkisch, Z. Révay, R. Gilles, H.A. GasteigerDOI: 10.1149/2.1341810jes

- Monitoring the Lithium Concentration across the Thickness of Silicon-Graphite Electrodes during the First (De-)LithiationM. Wetjen, M. Trunk, L. Werner, H.A. Gasteiger, R. Gernhäuser, R. Gilles, B. Märkisch, Z. Revay Journal of the Electrochemical Society 166(8), A1408 (2019)DOI: 10.1149/2.0581908jes